2015 Heidelberg SM XL 75-5 C

Description

BRAND: HEIDELBERG

MODEL: XL 75-5 C

Year of Manufacture: 2015

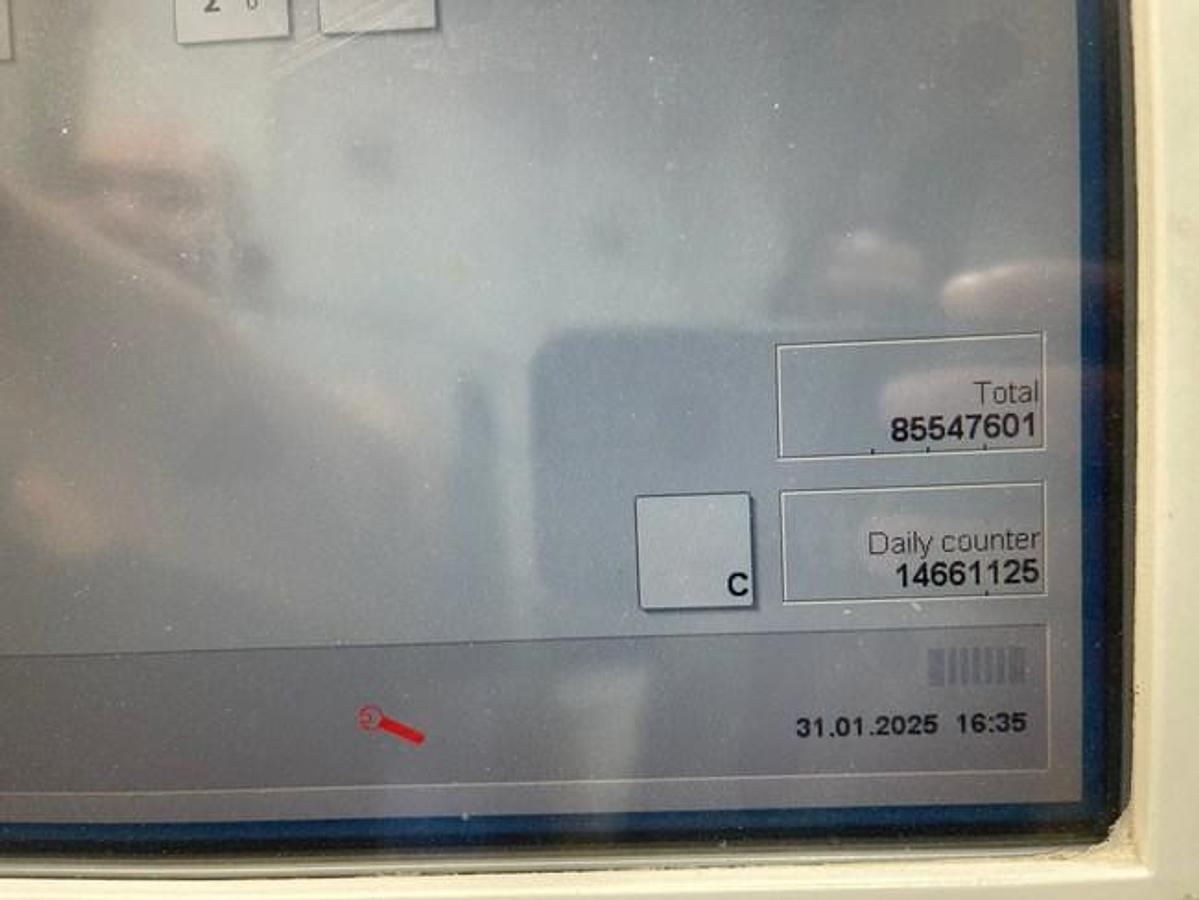

Impression: 92 Million only

*Equipped with:*-

Sheetfed Control ™? system

Modern patented press control system based on a new platform with decentralized drive control for the

feeder, printing units and delivery.

The control information is exchanged via CAN bus technology.

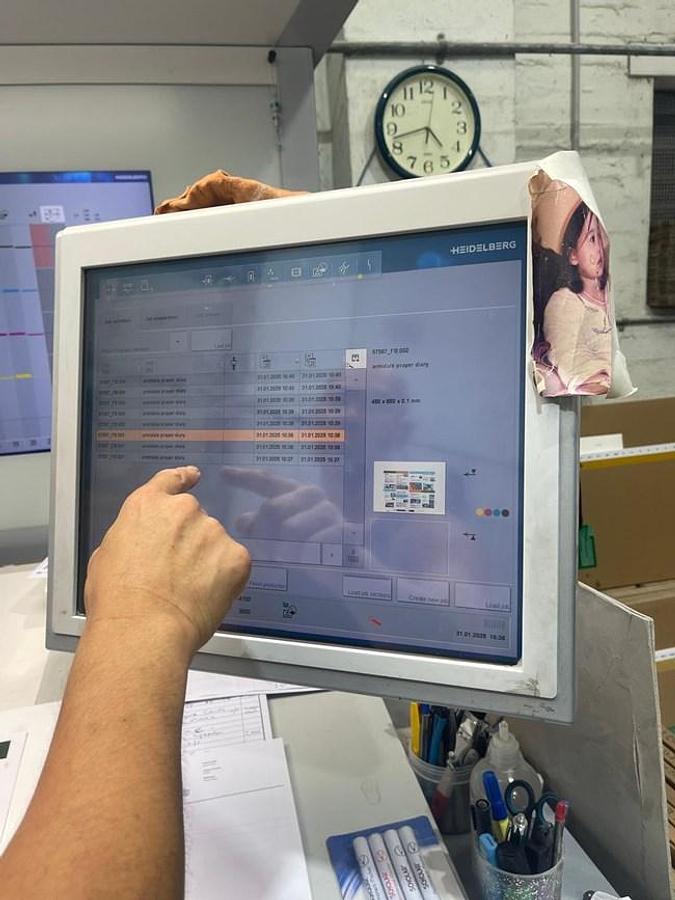

Prinect Press Center ™? with remote ink control

Prinect Press Center™? Control Console

High-quality 19" TFT touch screen

Freely movable and with adjustable inclination due to suspension from a bracket

Color display of graphics, symbols and text

• Intuitive operation by touching the screen

Effective protection against dust and water (class IP54)

Prinect Press Center™? Software

Preset Plus Feeder

Preset suction tape feeder

F e e d e r with 10.4" touch s c r e e n

• AutoPlate with Heidelberg register system; automatic plate changing system with pneumatic plate

clamping device not requiring any tools

• Double diameter impression cylinder

• Plate cylinder with 0.15 mm undercut

• Blanket cylinder with 2.3 mm undercut, designed for mounting pre-barred blankets

• Plate cylinders, blanket cylinders and impression cylinders are provided with refined cylinder

surfaces. These surfaces are corrosion and wear resistant and easy to clean.

• Manual, selective register correction of printing plate in all directions at rear edge split clamping bar

• Auto adjustment of plate dampening roller, inking rollers during diagonal adjustment of plate cylinder

• Preset blowing device at sheet infeed between blanket and impression cylinder assures a smooth

and stable sheet travel at higher production speeds especially on thin material

• Automatic blanket wash-up devices, program-controlled via Prinect Press Center ™? (for conventional

inks or mixed operation)

• Modular wash-up concept with user-friendly cloth roll change, low consumption of washing solution

and optimal use of cloth via partial rewinding mechanism

• Clamping bar for underlay sheet

• Double-diameter transfer between the printing units

• AutoPlate with Heidelberg register system; automatic plate changing system with pneumatic plate

clamping device not requiring any tools

• Double diameter impression cylinder

• Plate cylinder with 0.15 mm undercut

• Blanket cylinder with 2.3 mm undercut, designed for mounting pre-barred blankets

• Plate cylinders, blanket cylinders and impression cylinders are provided with refined cylinder

surfaces. These surfaces are corrosion and wear resistant and easy to clean.

• Manual, selective register correction of printing plate in all directions at rear edge split clamping bar

• Auto adjustment of plate dampening roller, inking rollers during diagonal adjustment of plate cylinder

• Preset blowing device at sheet infeed between blanket and impression cylinder assures a smooth

and stable sheet travel at higher production speeds especially on thin material

• Automatic blanket wash-up devices, program-controlled via Prinect Press Center ™? (for conventional

inks or mixed operation)

• Modular wash-up concept with user-friendly cloth roll change, low consumption of washing solution

and optimal use of cloth via partial rewinding mechanism

• Clamping bar for underlay sheet

• Double-diameter transfer between the printing units

Specifications

| Manufacturer | Heidelberg |

| Model | SM XL 75 |

| Year | 2015 |

| Condition | Used |

| Impressions | 93 Million |

| Availability | 2026-01-11 |

| Max sheet length | 750 |

| Max sheet width | 530 |

| Condition info | Very Good |